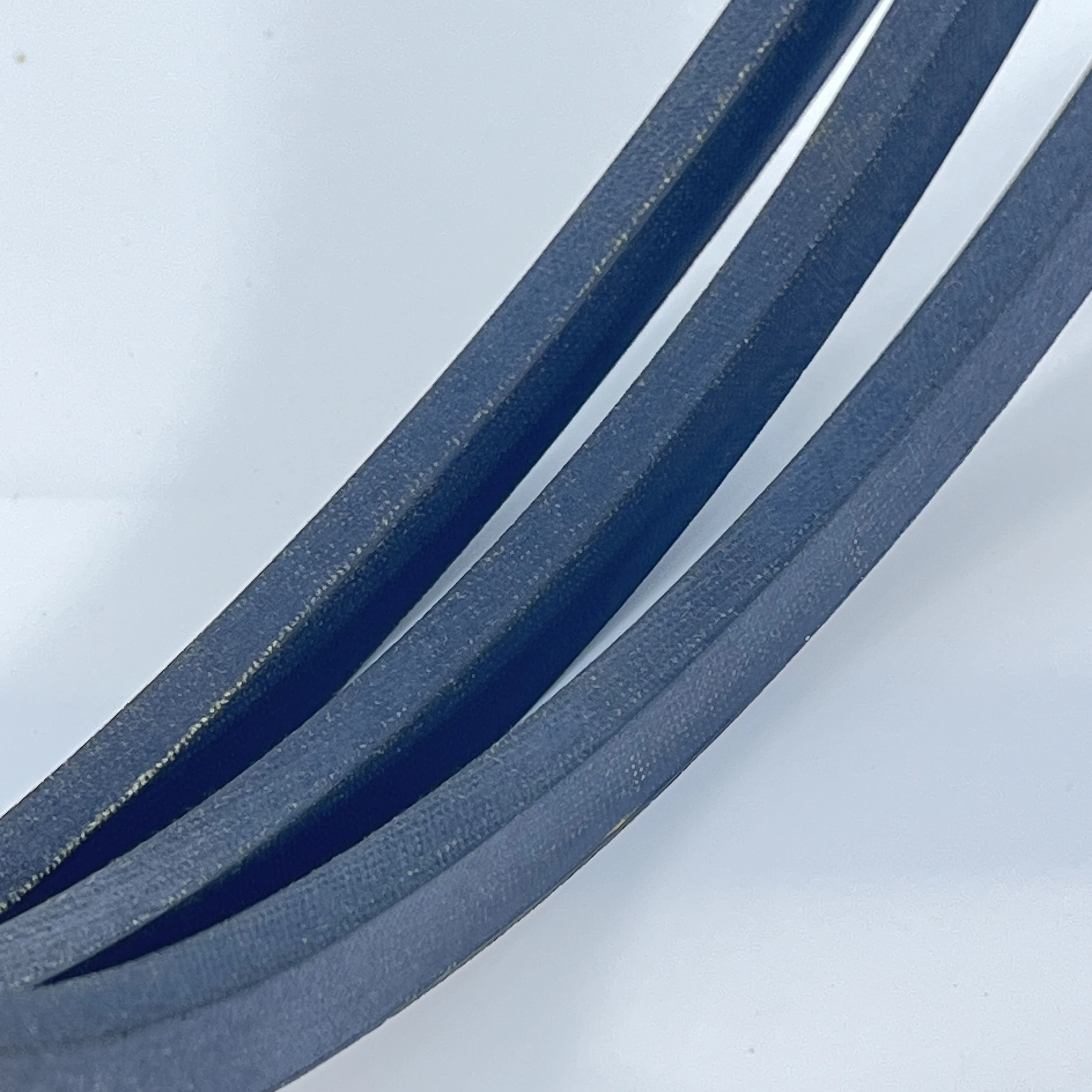

A component of a lot of units these banded cogged v belt is a useful thing in helping them to operate so properly. Those belts are sturdy and can assist in the machines running without issues. Find out more about what makes banded V belts ideal for use with industrial equipment.

All kinds of machines use banded V belts, such as those created by IIIMP MOTO POWER, to help them function and move properly. These belts are strong, and take a lot of the power of the motor. They’re also packed to fit perfectly in the machines, and that’s how they get such great work done.

Machines can perform better when they have cogged v belt that fit well and are in good condition. These belts allow the power to move and shift from one part of the machine to another flawlessly. That helps to make sure the machines run smoothly and do their jobs well.

It’s the same as we need to look after our toys to make sure they run properly machines needs maintained to make sure they are running well also. This includes inspecting the replacing a serpentine belt for signs of wear and tear. If they belts are in worn condition and worn out, they can be replaced by new belts from IIIMP MOTO POWER. Banded V belts being well maintained can be longer used, work better.

Band V belts are used in wide range of applications to make machines work. They can be found in factories that produce goods, on farms that use tractors and in cars and trucks. These ford fiesta timing belt are an important part of machine helping its work well.

By using superior quality IIIMP MOTO POWER automotive v ribbed belt can run stronger, longer and maintain optimal performance. They are made to be hard and endure a lot of wear and tear, that it no small feat for a belt. But when machines have strong banded V belts, they can run well for years and help us in countless ways.

Adhering to international standards with traceable production and rigorous quality control from raw materials to finished goods, we provide comprehensive after-sales support to ensure customer satisfaction, seamless cross-border logistics, and hassle-free long-term usage.

We offer full-service OEM/ODM collaboration—from custom R&D and prototyping to scalable manufacturing—backed by professional technical consultation and tailored product selection to meet specific client requirements and application challenges.

With a 45,000-square-meter facility and an annual production capacity of 11 million pieces, our operations are supported by a specialized R&D team of 20+ experts and over 60 patented technologies, ensuring precision engineering and high-volume reliability for both OEM and aftermarket clients.

Our rubber belts are engineered for superior performance in demanding conditions, combining durable materials and innovative designs to deliver longer service life, reduced downtime, and cost-efficient operation for industrial power transmission applications.