You may feel that changing the belt on your riding lawn mower is a very intimidating or difficult task, but it is neither! With the proper equipment and just a little bit of elbow grease, you will have your IIIMP MOTO POWER drive belt on lawn mower running for a long time to come.

To begin, ensure that your riding lawn mower is turned off and cool to the touch. You will also need a wrench or socket set to undo the bolts that secure the belt cover. There is an access cover that unscrews from the bottom of the vacuum that you’ll need to unscrew to remove the cover the old belt, and remove it and take a good look at how the old belt is in place so you can put the new one on the same way. Be certain the lawn mower drive belt replacement is the proper size and the V shape of the belt is riding in the groove located in the lawn mower pulley system.

Ensure it is properly aligned with the pulleys on your riding lawn mower. You might have to play with the tension of the belt, it shouldn't be too loose or to tight. Here is where things get a little tricky, make sure everything is lined up correctly before you put the belt cover back on. Having a steady and smooth hand will contribute to the process of peacefully doing the belt replacement without interruptions. Check out IIIMP MOTO POWER's mower drive belt replacement today!

When selecting a replacement belt for you, make sure it is the right size according to your owner's manual. Seek out belts constructed from sturdy long-lasting materials that can stand up to frequent use. You can also have a spare belt handy for emergencies to replace the belt fast if it gets wore out. Why not consider IIIMP MOTO POWER's mower deck belt replacement?

But if you encounter any issues in the belt replacement journey, this will help you! Also, make sure that the honda mower drive belt replacement is correctly on the pulleys and the tension is correct. If the belt continues to fall off or to emit odd sounds, you may have it installed improperly. just follow the steps be patient, it's not hard to change the turntable belt

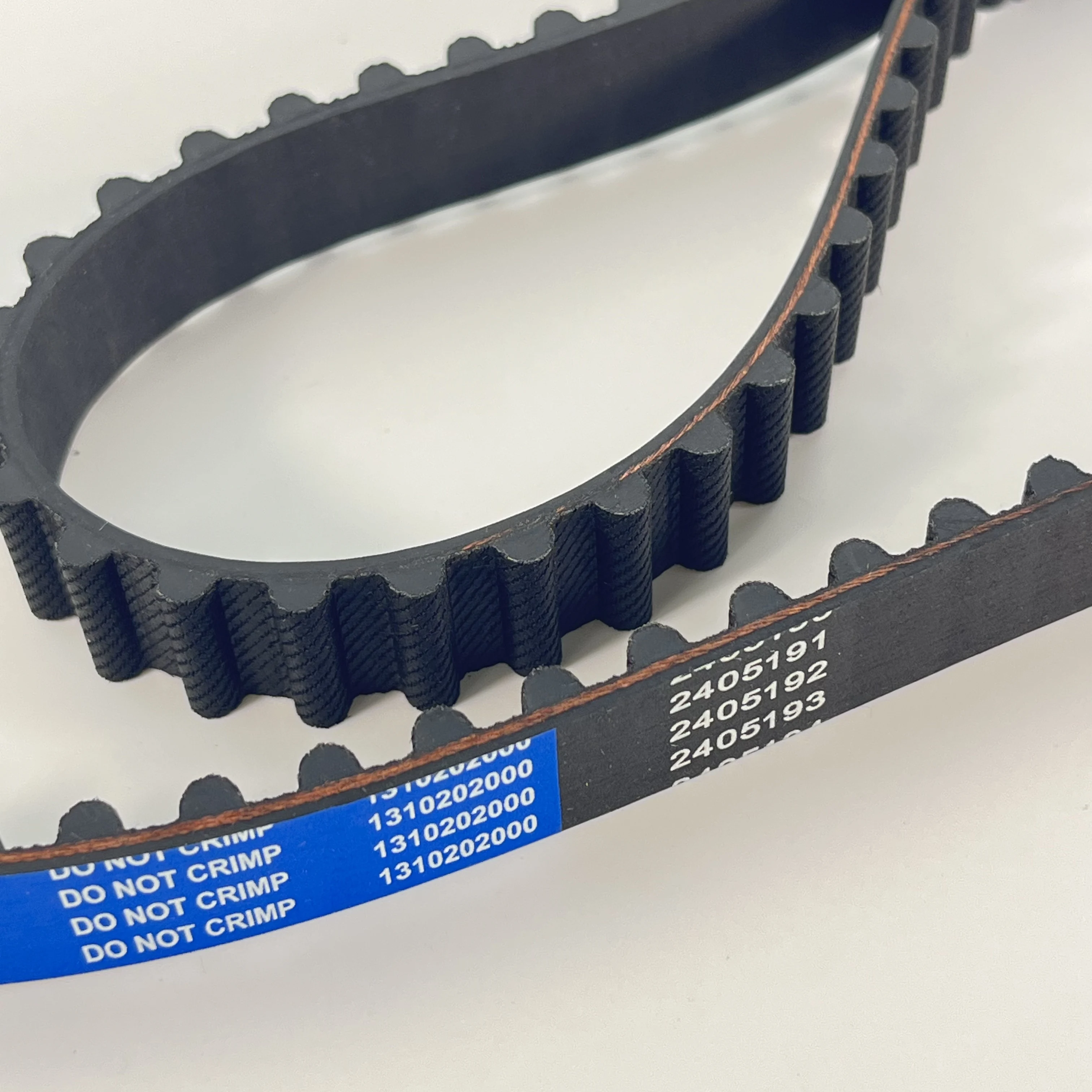

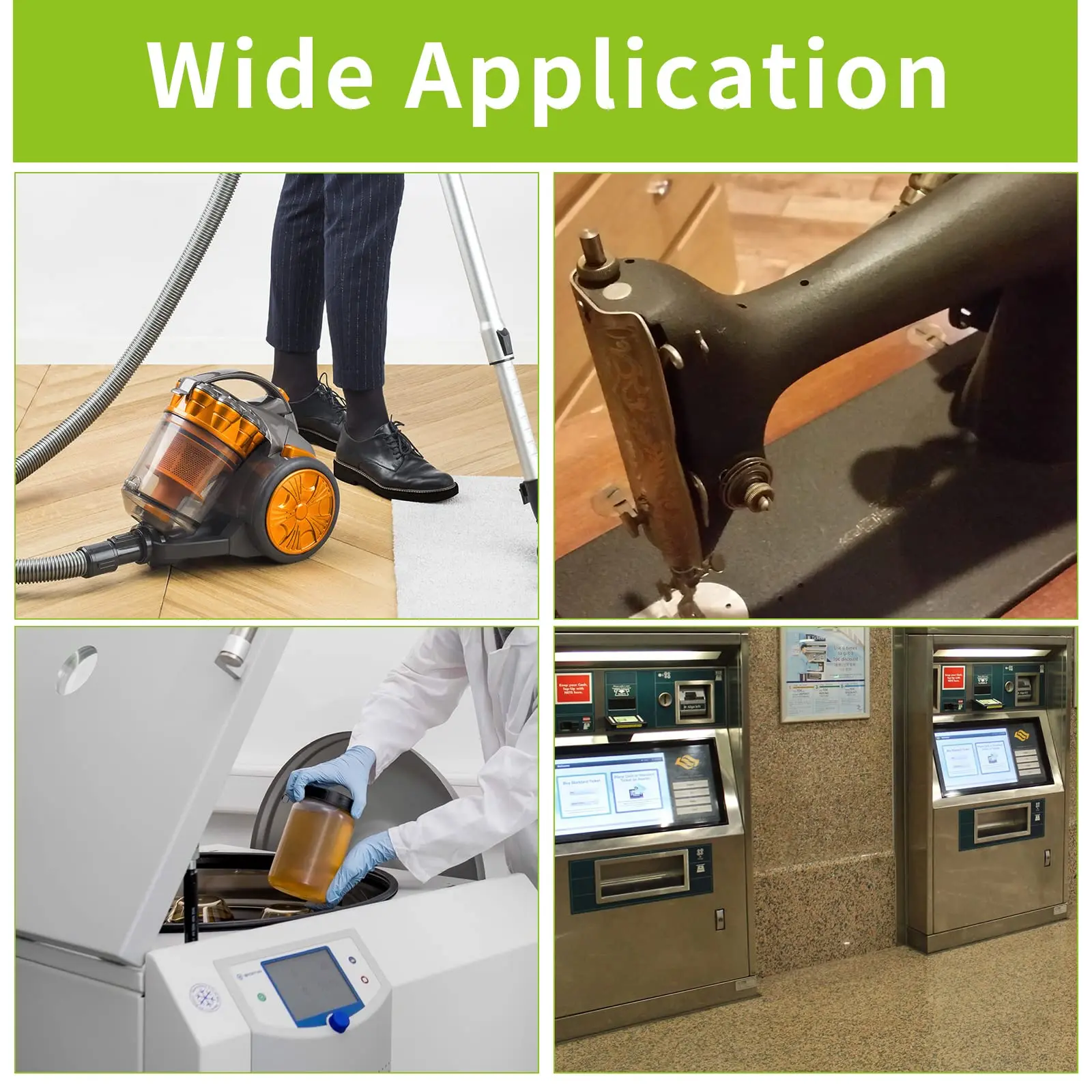

Our rubber belts are engineered for superior performance in demanding conditions, combining durable materials and innovative designs to deliver longer service life, reduced downtime, and cost-efficient operation for industrial power transmission applications.

With a 45,000-square-meter facility and an annual production capacity of 11 million pieces, our operations are supported by a specialized R&D team of 20+ experts and over 60 patented technologies, ensuring precision engineering and high-volume reliability for both OEM and aftermarket clients.

We offer full-service OEM/ODM collaboration—from custom R&D and prototyping to scalable manufacturing—backed by professional technical consultation and tailored product selection to meet specific client requirements and application challenges.

Adhering to international standards with traceable production and rigorous quality control from raw materials to finished goods, we provide comprehensive after-sales support to ensure customer satisfaction, seamless cross-border logistics, and hassle-free long-term usage.