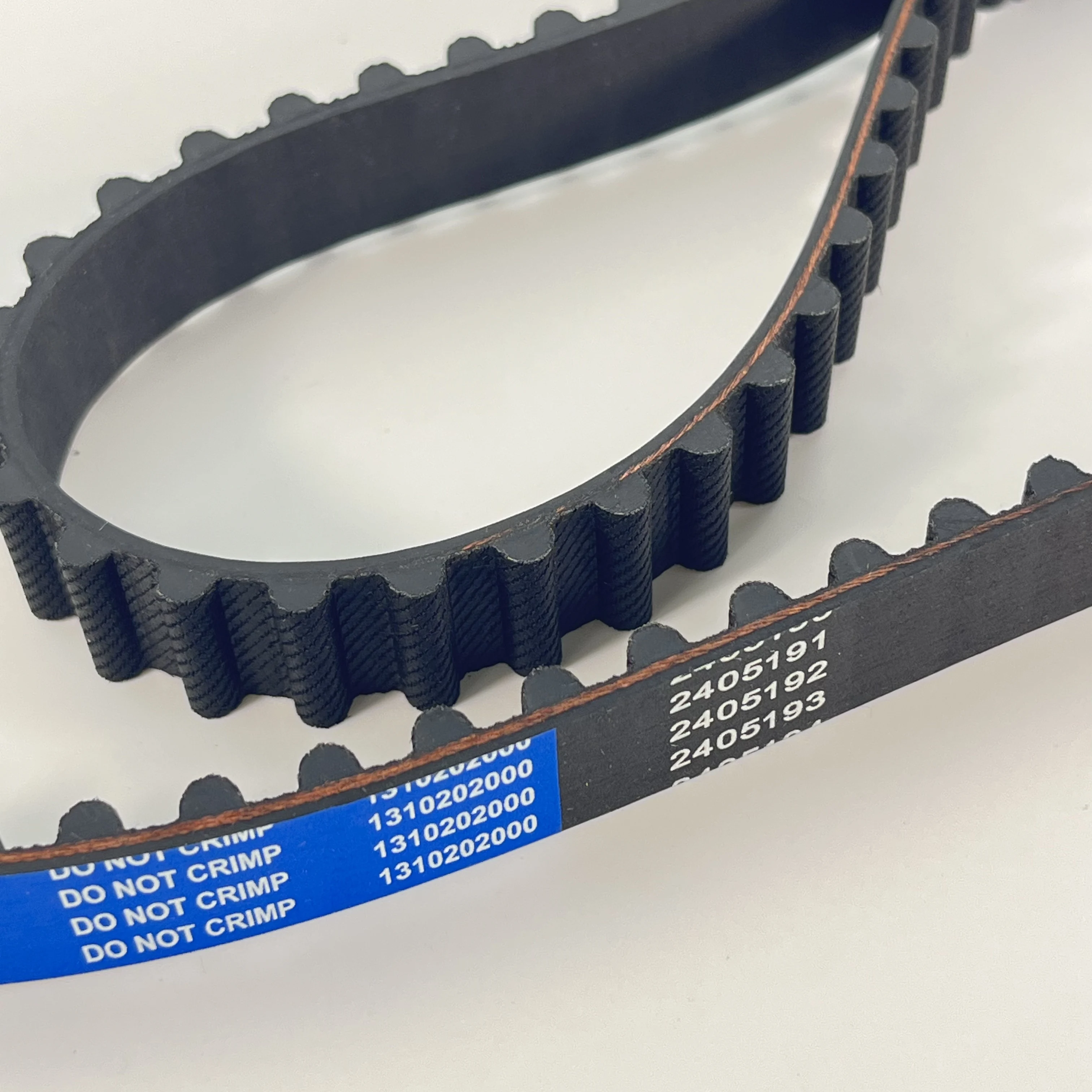

The serpentine belt in your Honda Accord is an important part of the engine. After all, it’s there to ensure everything works, allowing you to drive safely. It’s the thing that keeps everything together in a concert

Your vehicle can become problematic if the belt becomes worn or is broken. Inspecting the replacing a serpentine belt from IIIMP MOTO POWER regularly allows you to catch any problems early, so you can keep your car running smoothly.

If you hear your serpentine belt squeaking or squealing, that means it might be time for a new one. You may also know if your car is not driving or it lacks air conditioning. These are all symptoms that the car serpentine belt from IIIMP MOTO POWER really should be replaced.

If you’re feeling adventurous and want to see if you can change a serpentine belt yourself, here's a basic rundown of how you can. The first step is to find the belt under the hood of your car. Then, with a wrench, loosen the tensioner pulley so you can take the old belt off. Next, replace the new serpentine fan belt according to your car manual’s diagram. Finally, fit the tensioner pulley and ensure that the belt is in position. CONGRATULATIONS ON REPLACING YOUR SERPENTINE BELT!

To ensure that your serpentine belt lasts you a long time, here are a few things you can do. Be sure to inspect the belt periodically for any wear or damage. The belt should also be clean and free from material that could cause it to slip or break. And get that rubber belt replaced while you’re at it, based on your car’s maintenance schedule. By maintaining your IIIMP MOTO POWER's alternator serpentine belt, you can ensure that your car will be in smooth running condition for years to come.

The serpentine for your Honda Accord's engine is a lot like the engine itself - it just works. It's responsible for turning several of the engine's deep-seated components, like the alternator, power steering pump, and air conditioning compressor. Your car could not run without a serpentine drive belt. That’s why it is crucial to check the condition of the belt and replace it, as necessary

Adhering to international standards with traceable production and rigorous quality control from raw materials to finished goods, we provide comprehensive after-sales support to ensure customer satisfaction, seamless cross-border logistics, and hassle-free long-term usage.

With a 45,000-square-meter facility and an annual production capacity of 11 million pieces, our operations are supported by a specialized R&D team of 20+ experts and over 60 patented technologies, ensuring precision engineering and high-volume reliability for both OEM and aftermarket clients.

We offer full-service OEM/ODM collaboration—from custom R&D and prototyping to scalable manufacturing—backed by professional technical consultation and tailored product selection to meet specific client requirements and application challenges.

Our rubber belts are engineered for superior performance in demanding conditions, combining durable materials and innovative designs to deliver longer service life, reduced downtime, and cost-efficient operation for industrial power transmission applications.