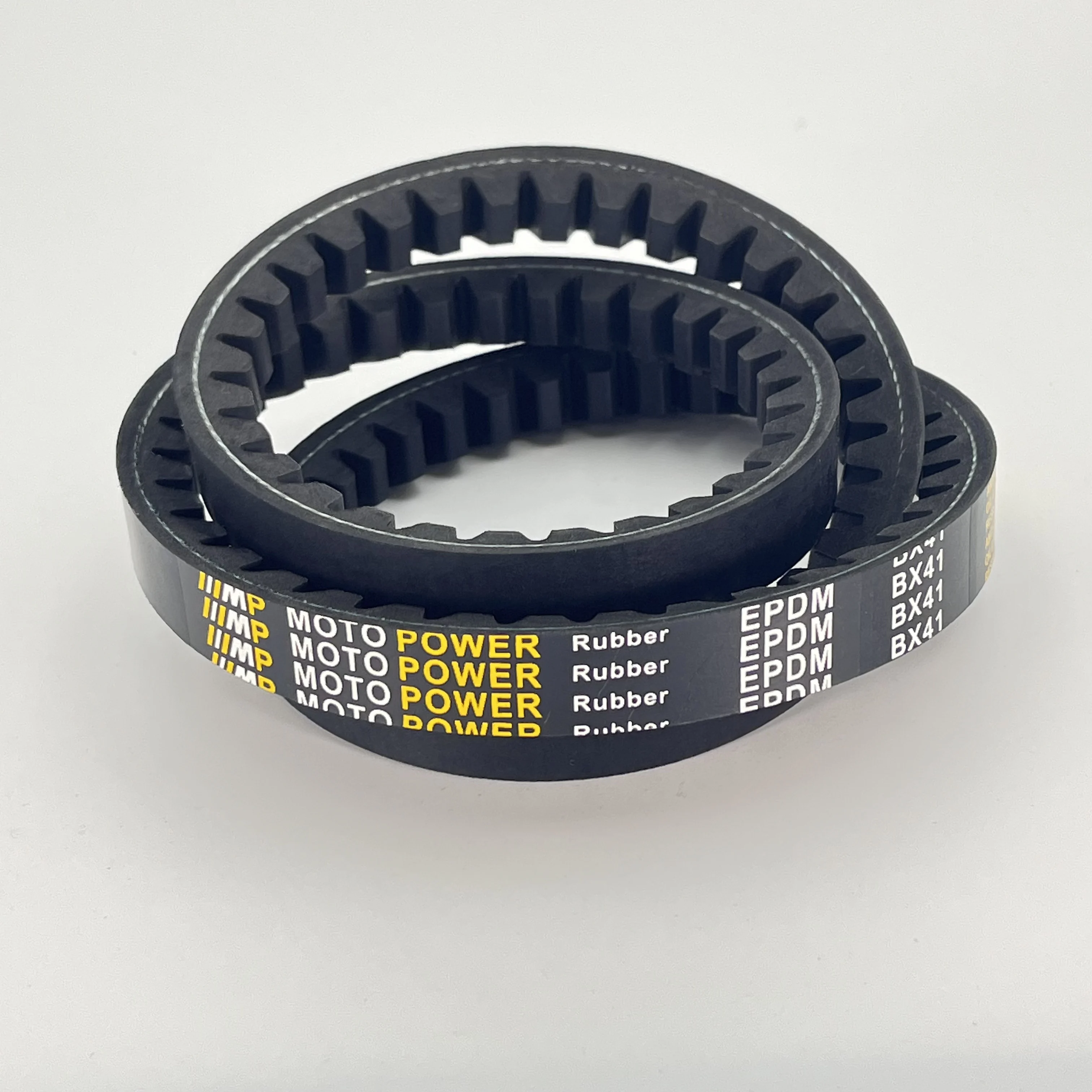

If there has ever been a machine with moving parts, it probably uses custom drive belts. These specialty belts keep machines humming along smoothly and efficiently. Custom drive belt replacement that fit multiple machines and devices are created by companies such as IIIMP MOTO POWER. Let’s find out why custom drive belts are crucial to industrial equipment & how they can save the day

Custom drive belts are the Superman of machines. They also help to pass power from one area of a machine to another, which ultimately allows all of the parts to function smoothly. Machines would not have the power that they do without custom drive belts. Such belts are produced from sturdy materials that can handle a significant amount of force and movement. With custom drive belts from IIIMP MOTO POWER, you can be sure that your equipment will not only perform at its best, but will continue to do so for a long time.

Industrial machinery is a bit like a giant puzzle – all of the pieces need to fit together perfectly in order for the machine to work properly. Custom drive belts are key to keeping all of the components turning in harmony. They regulate the speed and direction of moving parts, making sure that everything operates in unison. Custom Drive Belts There’s a world full of broken machinery that would’ve worked just fine without custom drive belts. IIIMP MOTO POWER knows the specific purpose of change drive belt for industrial based equipment, so they provide these robust belts for these machines.

We want to teach people what a good set of shoes can do for you when you want to run faster. Custom drive belts can take the performance of your machines to a whole new level. With engine drive belt replacement from IIIMP MOTO POWER, you can make your machines run stronger and longer. Because they are custom drive belts, they are made to fit your equipment perfectly with the added bonus of improving the performance of your equipment. If you have a big machine or a little machine, getting the right custom drive belts can be the difference between it running well and running badly.

No two machines are exactly the same which is why custom drive belts are imperative. IIIMP MOTO POWER custom-made belt drive replacement designed to fit your necessity. Whether you’re looking for a longer, shorter, wider, or narrower belt, they can create a bespoke belt that’s just right. Custom drive belts are built to fit and perform, increasing productivity while saving you money. Custom drive belts help to ensure that your equipment is performing at its best.

Don’t settle for standard on your machines when you can have custom! Custom Drives Belts provide many benefits you just can't get from off-the-shelf belts. Whether you need a high capacity, high speed, hot or cold, wet or dry belt, IIIMP MOTO POWER can provide you with a belt that matches your needs. All of our car drive belt replacement can be used in applications that may require a higher friction belt in your machinery such as Lawn & Garden applications, elevators, pullers, heavy duty conveyors, heavy-duty drives, home sewing machines, brick crushers, mowers and so on. Then why put up with standard and not the custom drive belts benefits

Adhering to international standards with traceable production and rigorous quality control from raw materials to finished goods, we provide comprehensive after-sales support to ensure customer satisfaction, seamless cross-border logistics, and hassle-free long-term usage.

We offer full-service OEM/ODM collaboration—from custom R&D and prototyping to scalable manufacturing—backed by professional technical consultation and tailored product selection to meet specific client requirements and application challenges.

Our rubber belts are engineered for superior performance in demanding conditions, combining durable materials and innovative designs to deliver longer service life, reduced downtime, and cost-efficient operation for industrial power transmission applications.

With a 45,000-square-meter facility and an annual production capacity of 11 million pieces, our operations are supported by a specialized R&D team of 20+ experts and over 60 patented technologies, ensuring precision engineering and high-volume reliability for both OEM and aftermarket clients.