The importance of precision in timing belts with regards to effective automated systems:

Think of a robot that reaches out to grab objects on an assembly line. The timing belt is the robot's heartbeat, ensuring everything ticks over at the right time. Timing belt is not accurate, and Robot action is slow or even does not move. This can shut down an entire production line, wasting time and money. So accuracy in timing belts is important to keep automated systems running smoothly and to maintain high productivity.

The significance of choosing the right timing belt with accuracy in grudge:

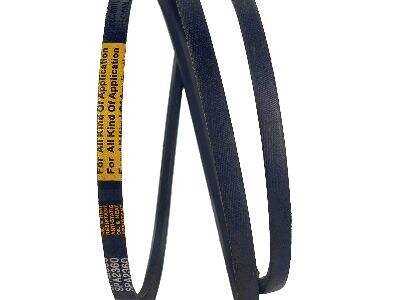

When selecting a timing belt size does matter. Various automation systems have varying requirements, and choosing a timing belt that meets those requirements is crucial. An overly loose or overly tight timing belt can result in issues such as slippage or breakage, and can interfere with proper functioning of the system. When you choose the right timing belt with accuracy in mind, you can help optimize your automation system.

Imagine, if you will, a car engine purring in good working order. The engine’s thick rubber belt governs when the valves open to allow air and fuel to mix in the combustion chamber at just the right moment. If that timing belt is off even a fraction of a second, the result might be a sputtering or stalled engine. The story is similar for automation as well – an accurate timing belt can be the deciding factor between your machinery running with the precision of a Swiss watch or a random conglomeration of whirring parts.

What does precision have to do with the proper functioning of timing belts in automation?

Accuracy is to a game of darts what hitting the bullseye is to the game itself — it’s a big deal when you get things exactly right. Though your timing belt rubber may seem like it plays a small role, it's an incredibly important part of your machinery. If the timing belt is so much as a millimeter off, it can disrupt the whole system and create a whole host of issues. And that's exactly why when you choose a timing belt, you should pay a close attention to accuracy since smooth operation is pretty important in automated systems.

Important considerations for accurate timing belt selection in automation:

There are a number of important factors to consider when selecting a timing belt rubber for an automated system. These factors include the size of the belt, the material from which it is made, and the type of teeth. It’s worth considering the environment that the automated system will operate within since things like temperature and humidity may affect how well the timing belt performs. By taking all these points into consideration, with accuracy in timekeeping, you can choose the best timing belt for your automated system and insure everything works well.

Table of Contents

- The importance of precision in timing belts with regards to effective automated systems:

- The significance of choosing the right timing belt with accuracy in grudge:

- What does precision have to do with the proper functioning of timing belts in automation?

- Important considerations for accurate timing belt selection in automation: