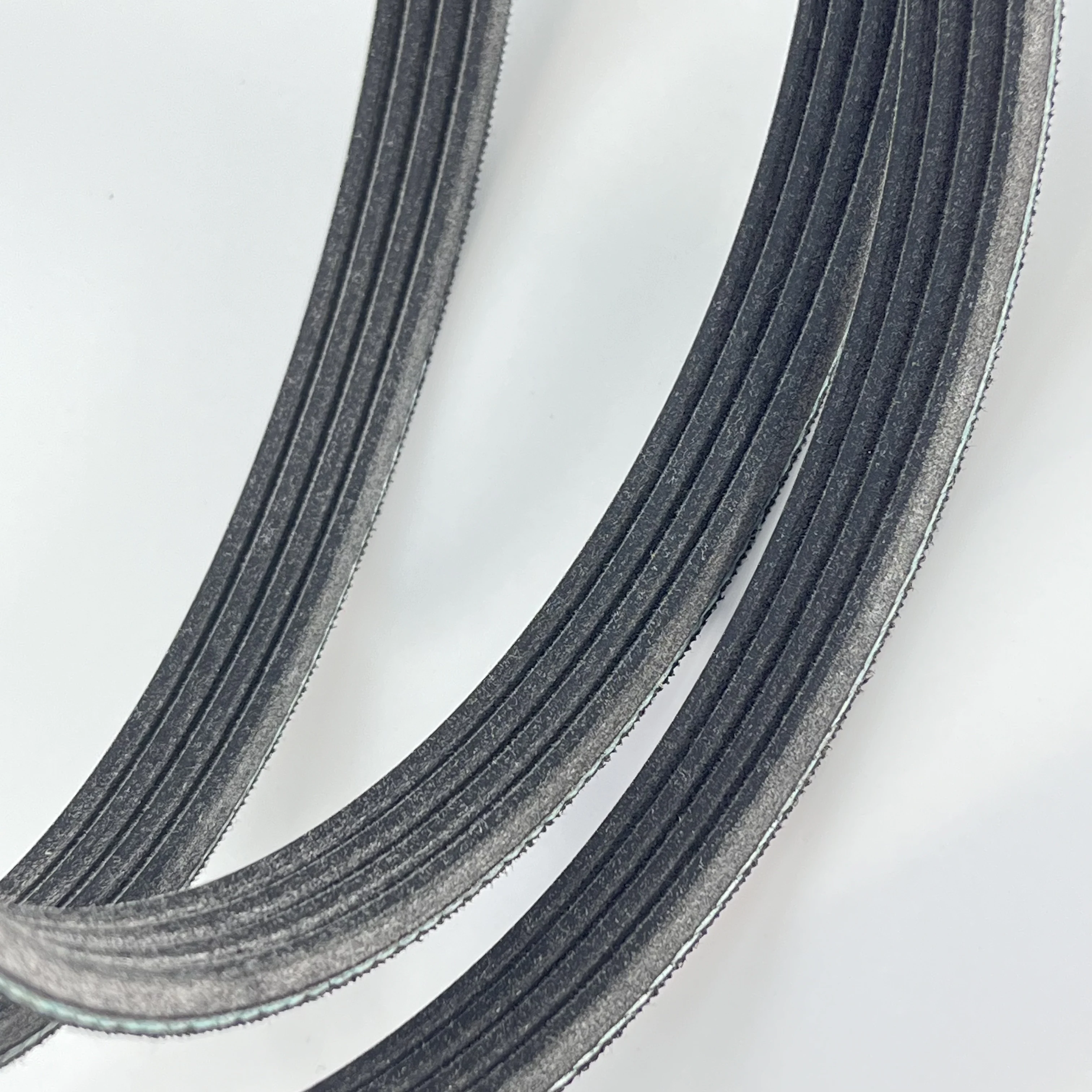

They help ensure everything is running smoothly on the inside of the car. Some of my best work. If the timing belt starts skipping teeth it can be ugly. That’s why it’s so important to read all about abrasion resistant conveyor belt and how to maintain them.

The timing belt is considered the conductor of the heart of your Honda Odyssey. And it also ensures that everything within that car operates in harmony with one another. It directs the movements of the components inside the engine, ensuring that all of these parts move in perfect time with each other. Without a timing belt, the motor would not function, and you would not be able to get moving in your car.

If you are the proud owner of a Honda Odyssey, then you must be aware of the timing belt interval. Typically, rubber toothed belt should be replaced after every 60,000 to 100,000 miles. But for each model of car, it’s never a bad idea to check your car’s manual to know what the manufacturer suggests. If you’re not certain, you can always ask a grown-up or even a professional to assist you.

Replacing the timing belt on your Honda Odyssey is an important part of maintaining the engine. Youll need to make sure to find an excellent quality on this engine rubber belt which works well on your auto. If you’re uncertain about which one to select, you can seek assistance at a car parts store or a mechanic shop.

When it does there are certain signs to watch for you start hearing unusual sounds from the engine, like ticking, you might be looking at a elastic rubber belt may also feel your car isn’t running as well as it used to be. If you do, have your timing belt inspected immediately.

You know that you need to maintain the thick rubber belt you want it to run great. You’ll want to have it looked at on a regular basis and then replace it. You can also help maintain the timing belt in good condition through the use of your car’s manual’s maintenance schedule. By maintaining your timing belt, you can help prevent your Honda Odyssey from ending up in shambles.

Adhering to international standards with traceable production and rigorous quality control from raw materials to finished goods, we provide comprehensive after-sales support to ensure customer satisfaction, seamless cross-border logistics, and hassle-free long-term usage.

With a 45,000-square-meter facility and an annual production capacity of 11 million pieces, our operations are supported by a specialized R&D team of 20+ experts and over 60 patented technologies, ensuring precision engineering and high-volume reliability for both OEM and aftermarket clients.

Our rubber belts are engineered for superior performance in demanding conditions, combining durable materials and innovative designs to deliver longer service life, reduced downtime, and cost-efficient operation for industrial power transmission applications.

We offer full-service OEM/ODM collaboration—from custom R&D and prototyping to scalable manufacturing—backed by professional technical consultation and tailored product selection to meet specific client requirements and application challenges.