When you look under the hood of a car or a motorcycle, what you see is a long, stretchy band made of rubber and a circlet or band. A alternator drive belt replacement that you could encounter is the B section belt. This special belt is vitally important in ensuring that your car runs like clockwork.

The B section belt is a veritable superhero that supplies energy to your vehicle's many accessories, like the alternator, water pump, air conditioning compressor, etc. Minus this belt, these parts wouldn’t be able to do their assigned job. Which is why it’s so important to check and maintain your B section belt to avoid those troubles when it comes to performance.

The primary task of the car drive belt replacement is to transfer power from the engine to the multiple systems in your car. As the engine moves, it twists the belt, transmitting power to other parts of the vehicle. Kn400t oil Filter This helps keep your vehicle on the road and in the game.

When it comes to business, everything from factory machinery and construction equipment to your own production equipment and tools will depend on you for selecting the proper honda mower drive belt replacement. Variety of machines to which the tendency at revolution is different, you can use a belt that matches the power and the situation. With the right B section belt for your machine can get the most out of your machinery and equipment.

Like with every other part of your car or equipment, maintenance is crucial to the snapper drive belt replacement to keep it in good condition. Check the belt for wear, including cracks and fraying, and replace if necessary. Belt tension should also be accurately set in order to avoid slippage and enable effective power transmission.

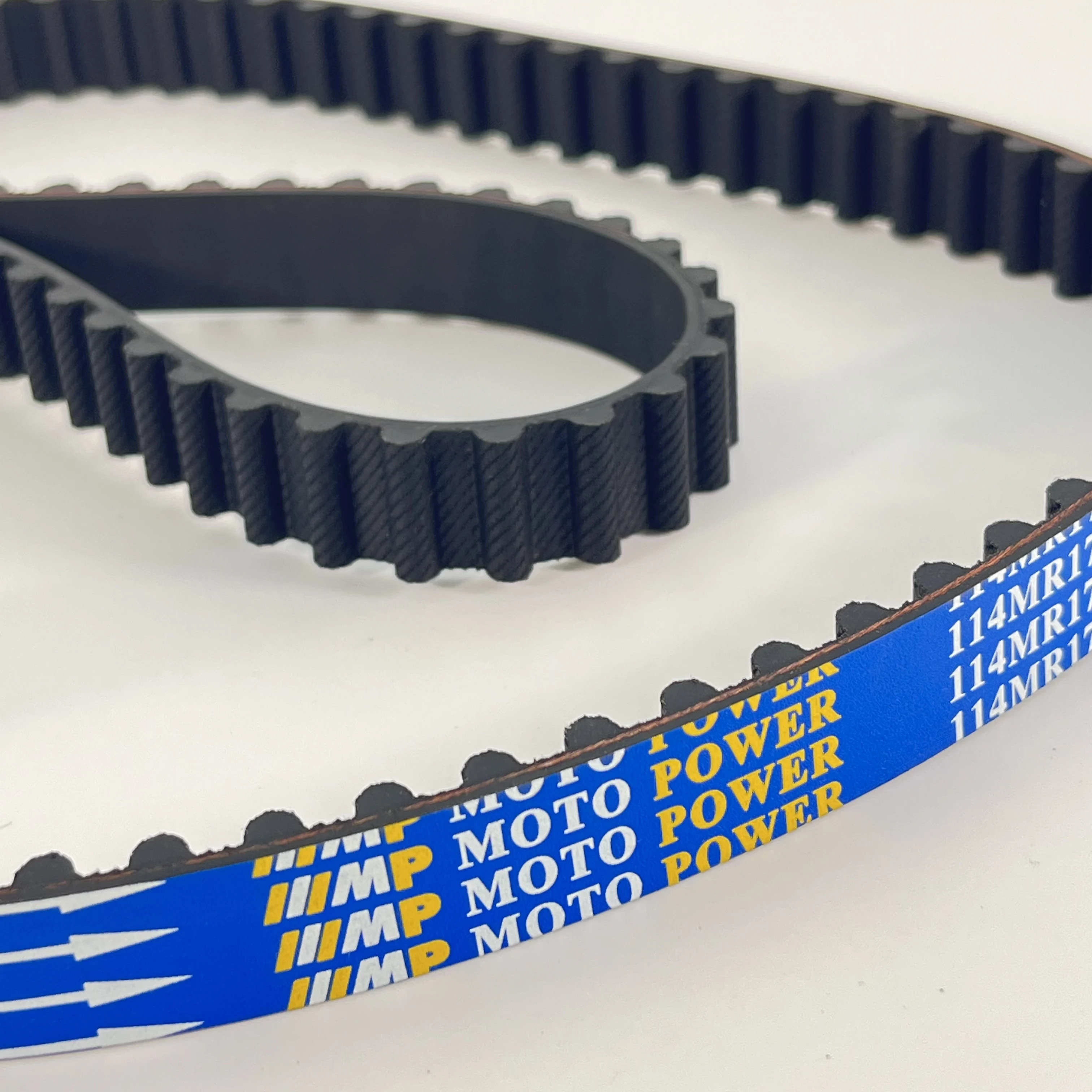

If you want to enhance your vehicle or equipment performance, then upgrade to a premium mower deck belt replacement from IIIMP MOTO POWER. These are high quality belts made to last a long time. A good B-Section V Belt is the secret to the reliability of your equipment.

Adhering to international standards with traceable production and rigorous quality control from raw materials to finished goods, we provide comprehensive after-sales support to ensure customer satisfaction, seamless cross-border logistics, and hassle-free long-term usage.

With a 45,000-square-meter facility and an annual production capacity of 11 million pieces, our operations are supported by a specialized R&D team of 20+ experts and over 60 patented technologies, ensuring precision engineering and high-volume reliability for both OEM and aftermarket clients.

We offer full-service OEM/ODM collaboration—from custom R&D and prototyping to scalable manufacturing—backed by professional technical consultation and tailored product selection to meet specific client requirements and application challenges.

Our rubber belts are engineered for superior performance in demanding conditions, combining durable materials and innovative designs to deliver longer service life, reduced downtime, and cost-efficient operation for industrial power transmission applications.