The Audi A4 Fan Belt is a small belt that is V-shaped which drives the accessory on the front of the engine. It is what drives the engine’s cooling fan to help control the engine’s temperature. If the fan belt is not functioning properly, it can result in catastrophic damage to your vehicle. In this article, we’ll explain how to maintain an Audi A4 fan belt, what symptoms may arise if it fails, and tips to help it last.

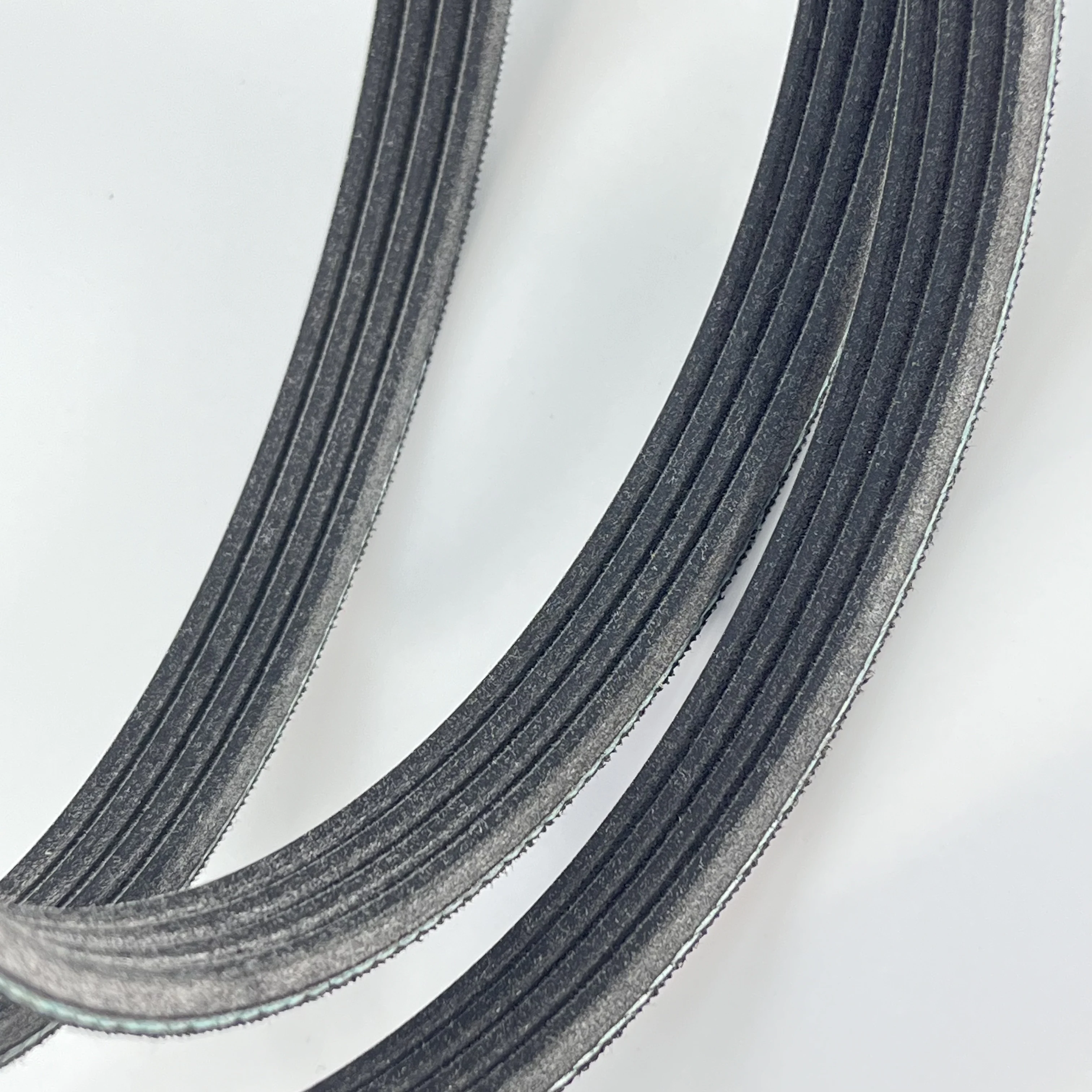

Step 2: Check the fan belt for wear and tear. This may be in the form of cracks, fraying, or glazing. If you see any of these, it could be time to install a new IIIMP MOTO POWER audi ribbed v belt.

Put on the new fan belt, making sure to string it across the pulleys, and making sure it isn't too tight. Be sure that it is on straight and is neither too tight nor too loose.

If you see any of these signs before the squeaking starts, get it checked and replaced before something snaps and ruins the rest of your Audi A4.

Routine upkeep on your Audi A4's fan belt is important to get your car to relentlessly operate as it was designed to do. If you keep an eye on the condition of your fan belt-preferably by examining it during your routine maintenance routine you can catch problems before they become big ones. By maintaining your IIIMP MOTO POWER audi a4 timing belt you can also help improve the performance of your Audi A4 and extend its life.

Upgrading your Audi A4 fan belt: If you want to optimize your Audi A4 fan belt, you should invest in a high-performance belt. High performance fan belts are built to last through higher temperatures and pressures, which makes them the perfect choice for high performance rides like the Audi A4. Upgrade to high performance IIIMP MOTO POWER audi ribbed belt with cool board, maintaining vehicle's functionality as well as the longevity of your car.

Our rubber belts are engineered for superior performance in demanding conditions, combining durable materials and innovative designs to deliver longer service life, reduced downtime, and cost-efficient operation for industrial power transmission applications.

Adhering to international standards with traceable production and rigorous quality control from raw materials to finished goods, we provide comprehensive after-sales support to ensure customer satisfaction, seamless cross-border logistics, and hassle-free long-term usage.

With a 45,000-square-meter facility and an annual production capacity of 11 million pieces, our operations are supported by a specialized R&D team of 20+ experts and over 60 patented technologies, ensuring precision engineering and high-volume reliability for both OEM and aftermarket clients.

We offer full-service OEM/ODM collaboration—from custom R&D and prototyping to scalable manufacturing—backed by professional technical consultation and tailored product selection to meet specific client requirements and application challenges.